|

Qingdao Foundry Machine Co.,Ltd.

|

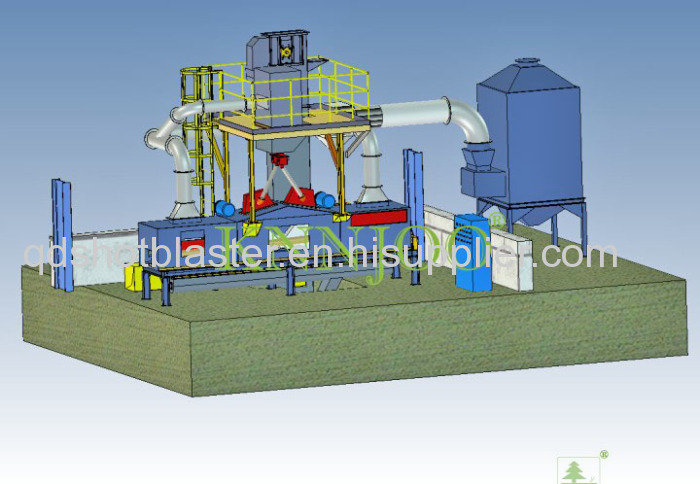

New Type Cleaning Equipment Spring Shot Blasting Machine

| Price: | 120000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Spring round spring strengthen shot blasting machine is used to strengthen the clean up various shafts, springs and other parts.

Describtion

Spring round spring strengthen shot blasting machine is the original introduction of the German technology company AGTOS a new type of equipment, special equipment is used to strengthen the clean up various shafts, springs and other parts. By strengthening shot blasting, not only can remove the workpiece surface rust and oil and other impurities, can also eliminate the internal residual stress of the workpiece and improve the fatigue strength of the workpiece, Almen reaches a predetermined value, rough Zhi and hardness, to prevent stress corrosion and artifacts fracture, and ultimately to improve the entire workpiece surface and internal quality.

The strengthening shot blasting machine has the following characteristics:

Access to materials and equipment used rotation speed frequency control, strengthen the work to ensure full Shot

Equipment uses a shallow pit design, installation and maintenance easy

Using a large shot volume, high velocity projectile curve blade centrifugal blast wheel disc single, significantly improve the cleaning efficiency, can achieve satisfactory cleaning quality.

Pill hopper and screw conveyor with income collected by the work out, scattered projectile

Have projectile in real time supplement supplements consumed by projectile

Have Shot cumulative time timer function to guide the replacement of the blast wheel blades and other wear-resistant parts

Simulated projectile drawing and drawing all shot blasting machines are completely computer-aided design (CAD) drawing, blasting the selection and arrangement more reasonable. Improve the utilization and labor productivity projectile to ensure that the cleaning effect, reduces the chamber body guard for wear.

Mn13 cleaning room for protection, to replace the simple, long life, is the best shot blasting equipment room guard plate.

Separator used by the US company Panbang En BE full curtain-type separator technology, good separation.

RDS-2MINI shot blasting machine:

RDS-2MINI shot blasting machine is the original equipment on the basis of independent development of a new type of equipment for strengthening special equipment to clean a variety of shafts, springs and other parts. By strengthening shot blasting, not only can remove the workpiece surface rust and oil and other impurities, can also eliminate the internal residual stress of the workpiece and improve the fatigue strength of the workpiece, reach the required cleanliness, roughness and hardness Zhi, prevent stress corrosion and artifacts fracture, and ultimately to improve the entire workpiece surface and internal quality. The strengthening shot blasting machine has the following characteristics:

1.The materials and equipment used in and out of the rotation speed frequency control, strengthen the work to ensure full shot

2.Equipment shallow pit design, installation and maintenance easy

3.Using a large shot volume, high-velocity projectiles single disk curve blade centrifugal blast wheel, significantly improve the cleaning efficiency, can achieve satisfactory cleaning quality.

4.Projectile with hopper and screw conveyor pill income collected by the work out, scattered

5.Blasting time with cumulative timing function to guide the replacement of the blast wheel blades and other wear-resistant parts

6.The simulation projectile shot blasting machine and all the drawings are completely computer-aided design (CAD) drawing, blasting the selection and arrangement more reasonable. Improve the utilization and labor productivity projectile to ensure that the cleaning effect, reduces the chamber body guard for wear.

7.The rolling Mn13 cleaning room for protection, wear-resistant shield nut, easy to replace, long life, is the best shot blasting equipment room guard plate.

8.The separator used by the US company Panbang En BE full curtain-type separator technology, good separation.

Our service

Quality and After-sale Assurance:

1. Supplier promise the name, model, specification and quantity comply with technical protocol,

assuring the machine is new equipment with qualified material manufactured through perfect technology.

There are no defects in design, material and technologies, which is suitable for propose of demander,

and meets the standard of national industry. The quality is stable and reliable.

2. Equipment warranty and After-sale Assurance Engineers available to service machinery overseas

( except force majeure, inappropriate operation and the quick-wear parts wears).

3. The equipment will pass the installment and test before delivery, after the quality is qualified.